No matter what type of business you’re running, if you’re selling a product, chances are that you will require some type of packaging. This is especially crucial if you’re shipping products or want to increase general shelf life.

Using vacuum sealers and heat sealers is two of the more common ways to package smaller products. How do these two sealing types work, and which will best suit your business? Keep reading to find out.

Safe and Secure Packaging is Essential

Online shopping is as big in Australia as it is around the world. This means that if you advertise your business online via an E-commerce store or your official website, you’re going to need packaging durable enough to withstand the rigours of shipping. With this in mind, our team of experts have compiled a few pointers that will help you understand the difference between cold and heat sealing processes.

Understanding the Cold Seal Packaging Process

Cold seal packaging is done using water-based adhesives that are commonly used to seal film and paper packaging material. Typically, cold seal is a self-sealing type of adhesion that only requires pressure to create an effective seal.

For the most part, cold seal packaging is the preferred option for temperature-sensitive products such as confectionery items, medical products, chocolate and even ice cream. To perform this type of seal, you only require pressure, but no heat.

Cold seal makes use of pressure-sensitive adhesives and only seals to itself. This is why it’s commonly referred to as “self-seal”. The process involves different types of bond strength, which range from low to high, depending on the strength of packaging you require.

Knowing the Pros of Cold Sealing

There are several reasons why some business owners prefer the benefits of opting for the cold sealing process. The most significant of these are listed as:

- Product protection: Opting for packages created from cold seal packaging eliminates having to fill space with filler material. Cold seal packaging creates a snug fit around the product, eliminating the risk of a small or delicate product getting damaged in shipping.

- Speed: Cold sealing is much faster than heat sealing. Depending on what you’re packaging, it can be as much as 10 times faster.

- Easier to open: In addition to being more durable on the outside, cold sealing is also easy to open and access the product.

- Reduces electrical costs: Cold sealing packaging equipment doesn’t require any heating elements, and you could see a significant saving in the cost of electrical consumption.

Knowing What Heat Seal Packaging Is

Heat sealing is currently the most commonly used package sealing method for small and large businesses. Many organisations prefer this type of sealing when a high-integrity seal is required, such as the shipping of delicate products that are at risk of damage.

Typically, heat seal packaging refers to the process where heat is used to melt the sides of specialised film together to create a sturdy seal. For packaging applications, heat sealing can be used to secure an existing bag or create an entirely new one from two sheets of poly film.

Unlike other types of packaging, heat sealing doesn’t require a special process or additional materials such as pressure-sensitive adhesives. This characteristic makes heat sealing a considerably more economical choice.

Pros of the Heat Sealing Process

Many will agree that heat sealing is an effective part of a successful packaging process. Here are the top benefits that make it obvious why:

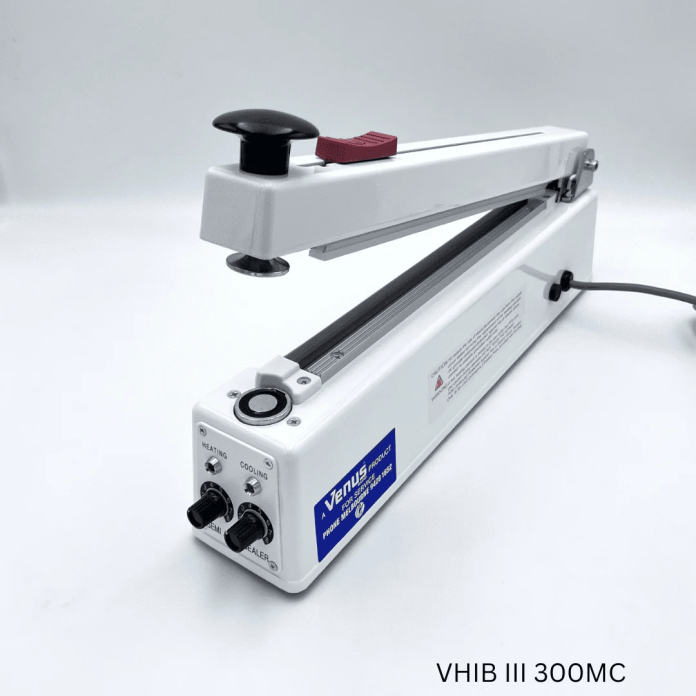

- Increases productivity: Heat sealing is quickly done with a heat sealing machine, which means there’s very little manual work involved. Using a quality heat sealing machine allows your team to pack more packages per session than you’d be able to if a person were sealing each package individually. An extensive range of heat sealers enables you to easily find the right option for your product needs.

- No adhesive required: In the heat sealing process, heat is used to seal two pieces of plastic film together. This means that there’s no need for additional adhesive. As with a vacuum sealer, this eliminates the costs associated with pressure-sensitive adhesives.

- Creates a protective material: Some shipping processes involve a large amount of handling and external conditions before reaching their intended destination. This can include harsh weather and human contact during an extensive shipping process. The film used and the combination of the heat create a strong and sturdy package that protects your product from handling and weather.

- Creates a tamper-evident seal: Opting for heat heat-sealing machine means you’re also creating a tamper-evident seal. This means your customers will easily be able to identify whether or not products have been tampered with after the sealing process.

Final Thoughts

Both heat and cold sealing are effective forms of packaging. The option you choose depends largely on what you need to package, how important shelf life is, and how protected your items need to be during the shipping process. Speak to your packaging expert for the best equipment and process for your specific product.