Using an FDM 3D printer is beneficial as the 3D printing industry continues to gain popularity. 3D printers, in general, are versatile – you can use them in a wide range of applications. An FDM 3D printer is the most popular 3D printer among 3D printers.

Reading this article will enable you to understand FDM 3D printers. You’re going to understand:

- How an FDM 3D printer works

- FDM 3D printing applications

- How to successfully print a 3D model using an FDM 3D printer

- Pros and cons of using an FDM 3D printer

Let’s dive in!

How Does an FDM 3D Printer Work?

Fused Deposition Modeling (FDM) 3D printers are also called Fused Filament Fabrication (FFF). An FDM 3D printer uses additive manufacturing technology to produce high-quality 3D models.

Check this out:

FDM 3D printers use thermoplastics as their primary printing materials. The printer works by first melting the thermoplastics. It then extrudes the molten thermoplastic through a nozzle in a predetermined path.

Here’s something worth noting:

There are two types of FDM 3D printers:

- Single extruder – single extrusion FDM 3D printers have a single extruding nozzle. The best part about using this type of FDM 3D printer is that it is stable, precise, and prints smooth 3D models quickly.

- Dual extruder – dual extrusion FDM 3D printers have two extruding nozzles. This printer can take two thermoplastic filaments and print two 3D models simultaneously. The best part about using dual extrusion 3D FDM printers, apart from printing two models simultaneously, is that it improves your productivity.

How Should You Print a 3D Model Using an FDM 3D Printer?

Now, two major steps are required to print a 3D model using an FDM 3D printer. Check them out:

1. 3D modeling and design – the modeling and designing phase can be easy or intimidating, depending on your design skills and the complexity of the model you want to print.

Technical designing is done using computer-aided designing (CAD) software.

However, most people download pre-designed complex 3D models, e.g., anime figurines, architectural models, etc. Downloading the pre-designed file saves you a lot of time and guarantees you a well-detailed 3D printout.

Here’s something worth noting:

3D printers generally have minimum and maximum model sizes that they can print. It is essential to ensure that the 3D model you’ve designed or downloaded conforms with the minimum or maximum print size capability of your 3D printer.

2. After completing the modeling and designing phase, you’ll need to export the file (usually in .stl format) to the slicing software. Slicing software is different from CAD software.

Slicing software is responsible for model slicing – converting a 3D model into a format that the FDM 3D printer understands (g-code).

A 3D printer’s slicing software’ slices’ (quite literally) the soft copy 3D model into smaller layers and instructs the printer how to print each layer of the 3D model. After slicing, you’ll need to copy the sliced file to the FDM 3D printer.

The printer should now be able to print your desired 3D model without any issues.

It would be best for you to use slicing software from your printer’s manufacturer.

Please note that printing 3D models with complex geometries will undoubtedly require the use of support material. Support material should be removed from the primary 3D model after the complete printing process.

Where is an FDM 3D Printer Mainly Used?

An FDM 3D printer is usable in a wide range of industries. Most industries, e.g., automotive, consumer goods manufacturer, etc. One of the primary reasons why FDM 3D printers are the most popular 3D printers is because they are practical and economical.

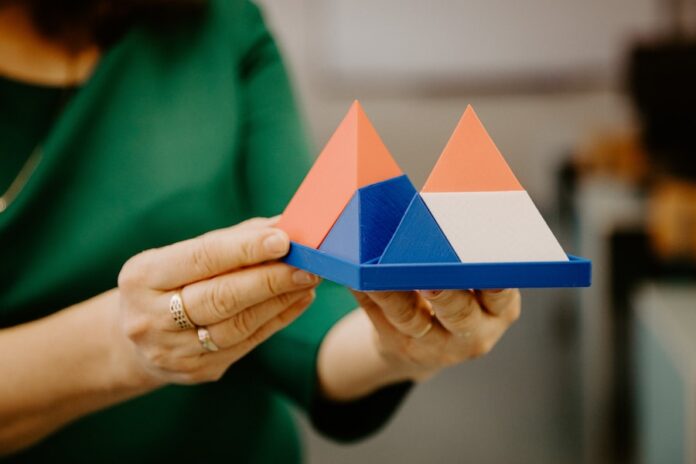

They can also be used to print various products, e.g., children’s toys and consumer goods such as bottles, etc. Check out the main categories of applications for an FDM 3D printer:

Prototyping

Traditional prototyping, e.g., injection molding, can be difficult and time-consuming. The introduction of 3D-printed prototypes has made the process more efficient and economical.

An FDM 3D printer can print functional and non-functional prototypes depending on your choice of thermoplastic filament. Prototyping is an essential stage of developing a functional product as it helps you understand the overall design of a component.

Rapid prototyping enables you to design a final functional product with the right proportions. Remember, slight proportional adjustments can alter the performance and functionality of your desired component.

Medical Industry

FDM 3D printers are also used in the medical industry to make geometrically basic models that do not need many intricate details. It is additionally used to create prototypes for surgical guides and tools, some of them being sterilizable.

Experts have made several attempts to print prosthetics with simple geometries. However, the results were not entirely promising because the FDM 3D-printed prosthetics were unsuitable for functional applications.

Automotive Industry

An FDM 3D printer is an asset to the automotive industry as it enables car manufacturers to print plastic car components quickly.

Here’s the best part about using FDM 3D printers in the automotive industries:

The printed components are tough and lightweight, which is unquestionably vital as it reduces the car’s overall weight. Additionally, the cars perform better and are economical on energy consumption.

Consumer Products

Small consumer products, e.g., bottles, and children’s toys such as dolls, etc., can easily be printed using FDM 3D printers. Manufacturers can quickly develop a design, print it, and avail it for sale in local and international markets.

What are the Advantages of Using an FDM 3D Printer?

There are three primary advantages of using an FDM 3D printer. Check them out:

Economical

FDM 3D printers are economical, which is why they are the most popular 3D printers. Businesses and enthusiasts will find this printer’s economic feature beneficial as keeping costs low is vital.

Apart from the printer being economical, its printing materials (thermoplastics) are also cheaper than other printers’ printing materials.

Wide Selection Range of Thermoplastics

Using an FDM 3D printer enables you to enjoy selecting a wide range of thermoplastics used to print models for different applications. In addition, these materials are economical.

Selecting a suitable thermoplastic is vital as it determines the success of your printed 3D models. Remember, complex design requires the use of removable support materials.

Quick Printing of 3D Models

Both single and dual extruding FDM 3D printers offer quick printing of 3D models. However, the single extruding is faster than the dual extruding printer; the latter prints two models simultaneously.

Therefore, you can use this FDM 3D printer to print, test, and alter 3D models quickly.

What are the Disadvantages of Using an FDM 3D Printer?

There is one primary disadvantage of using an FDM 3D printer. Check it out:

Warping

There is one primary demerit associated with using FDM 3D printers – warping. FDM 3D printers print 3D models by extruding molten thermoplastics. Different thermoplastic parts will cool and solidify at different rates, which may cause the warping of 3D-printed models.

However, you can handle warping effectively by monitoring the temperature of your FDM 3D printer. Consider checking the printer’s chamber and building the platform. You can additionally mitigate warping by increasing adhesion between the cooling 3D model and the build platform.

Here’s a summary of the Advantages and Disadvantages:

| Pros | Cons |

| Economical – FDM 3D printer and thermoplastics | Warping of 3D printed models |

| Wide selection of thermoplastics | |

| Rapid printing of 3D models |

Final Thoughts – What Makes FDM 3D Printers Popular?

If you are looking for a cost-effective way to print 3D models easily and quickly, consider getting an FDM 3D printer. It is ideal for use in many industries, e.g., prototyping, automotive, health, etc.

It is ideal for use in both industrial and home applications. Models with complex geometries should be printed together with a support material that is removable at the end of the printing process.

Bottom line:

FDM 3D printers are popular and are here to stay because they are:

- Cost-effective.

- Versatile – they are usable in many industries, e.g., automotive, medical, etc.

- They can use a wide range of printing materials that are also economical.