Thermal imaging is often described as futuristic, but the idea behind it is old, quiet, and deeply physical. Every object above absolute zero degrees emits infrared radiation. As temperature rises or falls, the radiation emitted changes. A thermal imaging camera simply watch for that signal.

Unlike a visible light camera, which depends on ambient light reflected in the visible range, thermal imaging detects infrared energy released by objects themselves. That distinction explains why thermal imaging devices work at night, through smoke, and in difficult weather conditions—and why night vision and thermal imagers are not the same thing.

A thermal camera converts thermal energy into a visible light display on the camera’s display, revealing temperature differences, thermal contrast, and heat signatures invisible to the human eye.

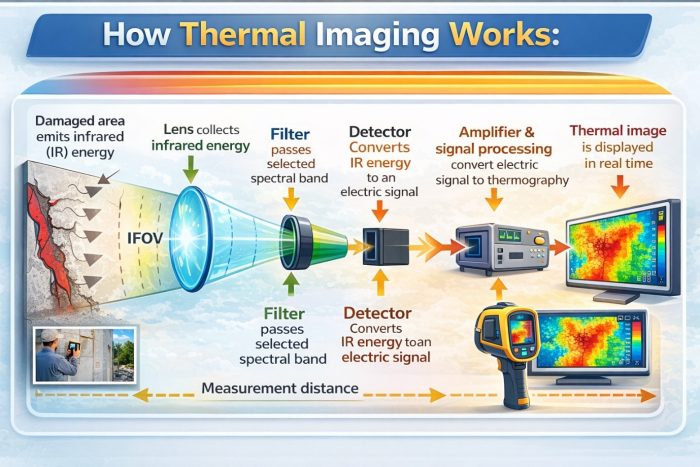

How Thermal Imaging Works

At the heart of all thermal imaging systems is a simple chain of events. Infrared rays—a form of radiation—are collected by optics and focused onto infrared sensors. These sensors measure infrared energy across a defined temperature range and translate it into electrical signals. The result is visual information representing temperature variations across a scene.

Modern thermal cameras and sensors are designed to detect temperature differences as small as a few hundredths of a degree, a level of high thermal sensitivity that allows operators to distinguish hotter areas, cooler areas, and subtle heat loss patterns seeing the details of people and objects well.

Because thermal imaging relies on radiation emitted, not reflected light, it does not require ambient light. That single fact explains why infrared thermal imaging cameras outperform visible light cameras in darkness, fog, and through obscurants like tree foliage.

Thermal Imaging Cameras and the Infrared Spectrum

Not all infrared cameras see the same world. Infrared technology spans different wavelengths, each interacting differently with air, moisture, and materials. Each working better or worse in different environments.

Many thermographic cameras operate in the long wavelength infrared band, where objects near ambient temperature—including humans with normal body temperature—produce strong thermal signatures. These thermal imaging cameras are common in building diagnostics, building inspections, and persistent security monitoring.

Other thermal imagers operate at mid wave infrared bands, detecting hot objects, exhaust plumes, or rapid temperature changes. Across all cases, thermal imaging depends on how infrared radiation travels through the atmosphere and interacts with different materials.

Uncooled and Cooled Thermal Cameras

Most modern thermal imaging cameras use uncooled focal plane arrays in the long wave infrared region. These uncooled arrays measure changes in thermal energy directly, without active refrigeration. The absence of cooling systems reduces size, power, and cost, making these thermal imaging devices well suited for mobile platforms and industrial applications and lower cost.

High-performance thermal cameras use cooled counterparts, where infrared detectors operate inside a vacuum sealed case at a lower temperature. Cooling the sensor material increases sensitivity, enabling longer detection ranges and improved performance in challenging weather conditions. Both approaches rely on advanced FPA sensors designed to convert infrared energy into precise electrical signals.

Leading companies like Clear Align enhances the capabilities of their thermal imaging cameras further through sophisticated software-based image enhancement techniques. These advanced algorithms dramatically improve image quality and sensitivity by reducing noise, sharpening thermal contrast, and optimizing temperature differentiation. This software-level enhancement allows operators to detect finer temperature variations and clearer thermal signatures, even in challenging environments, thereby significantly boosting the effectiveness and reliability of Clear Align’s thermal imaging devices.

Thermal Imaging vs. Night Vision

Confusion between night vision and thermal imaging is common. Night vision amplifies visible light and near-infrared reflections. It fails without ambient light. Thermal imagers detect heat, not light.

That is why thermal imaging cameras can locate a person hidden in vegetation, track a vehicle long after shutdown, or identify a heat signature through smoke—while a visible light camera shows nothing.

Passive and Active Thermography

Most security and surveillance thermal imaging systems use passive thermography, relying solely on naturally occurring thermal energy. This approach dominates perimeter monitoring, search and rescue, and wide-area observation.

Active thermography, by contrast, introduces an external energy source to stimulate thermal contrast. This method is widely used in scientific research, thermographic inspection, and evaluation of electrical and mechanical systems.

Engineers use active thermography to find hot spots, subsurface defects, and abnormal heat loss patterns in mechanical systems and electrical systems.

Building Inspections and Industrial Use

For building inspectors, thermal imaging has become essential. Thermal imaging cameras help detect heat loss, locate air leaks, identify wet insulation, and evaluate building envelopes without invasive testing.

In building inspections, thermal imagers reveal insulation failures, moisture intrusion, and inefficient electrical systems. In factories, thermal imaging devices monitor rotating equipment, detect overheating components, and protect critical infrastructure.

Across these industrial applications, thermal imaging turns invisible radiation into actionable insight.

Why Thermal Imaging Matters

The value of thermal imaging lies in its reliability. It works when visible light fails. It functions across temperature extremes. It reveals thermal signatures shaped by physics, not lighting conditions.

As infrared technology advances, thermal imaging cameras continue to improve in resolution, sensitivity, and cost efficiency. What remains constant is the principle: objects emit infrared radiation, and thermal imaging lets us see it.

In a world that increasingly operates in darkness, complexity, and uncertainty, thermal imaging is not just another sensor. It is a way of understanding heat, temperature, and motion—long before they become visible to anyone else.

Clear Align: A Leading Provider of Thermal Optics, Thermal Cameras and Thermal Systems in the USA

Clear Align stands as the largest privately held provider of thermal imaging solutions in the United States, supporting critical programs across the nation. With a strong commitment to innovation and reliability, Clear Align supplies advanced thermal solutions for key drone programs, border surveillance, and warfighter portable systems. Their thermal imaging devices are also integral to ground vehicle applications, providing enhanced situational awareness and security.

What sets Clear Align apart is their comprehensive approach to thermal imaging technology. The company delivers solutions across the entire thermal imaging food chain—from high-quality optical components and precision assemblies to fully integrated cameras and complete thermal imaging systems. This end-to-end capability ensures seamless integration and optimized performance at every level, allowing Clear Align to tailor solutions precisely to the needs of diverse applications.

By partnering with Clear Align organizations benefit from cutting-edge infrared technology tailored to meet demanding operational needs, making them a trusted name in the thermal imaging industry with advanced assembly and testing.