The UAE is the centre of some of the world’s harshest industrial environments, such as oil and gas, power generation, petrochemicals, desalination, metals, and cement production, as well as large-scale utilities. These are industries that operate under tough conditions, such as pipelines operating at high pressure, furnaces and boilers reaching very high temperatures, and equipment exposed to abrasive or corrosive media. In these environments, accurate temperature is more than just a process need; it is a safety, performance, and quality imperative, and critical to meeting regulatory and equipment longevity goals.

Therefore, temperature sensors cannot come into direct contact with the process. And that is where a thermowell comes in. The device does its job by offering robust mechanical insulation for reliable and precise temperature measurements, even at the most demanding system conditions within the industry in the UAE.

What Are Thermowells?

A thermowell is a pressure-tight receptacle in which the temperature-sensing element can be withdrawn without disturbing the system. Its primary function is to protect these sensors from direct contact with process media, hot fluids, corrosive chemicals, steam slurry, or high-velocity gases.

Inserting this device into a pipeline or vessel allows the temperature sensor to be protected while also providing an accurate measurement of process temperature. As a result, there are many advantages in the demanding UAE applications:

- Physical barrier to pressure rushes, flow stream forces, corrosion, and wear.

- Stable and precise temperature measurement also in unsteady flow conditions.

- The longer lifetime of the sensor, maintenance, and replacement period is extended.

- It is easy and safe to replace the sensor without halting the process. They are a must under the conditions where downtime is costly and safety margins are slim.

Engineering Requirements for High-Pressure and Temperature Thermowell Applications

To work safely under such conditions, a thermowell must satisfy rigorous engineering standards.

1. Material Strength

The following are some of the high-strength and corrosion-resistant alloys:

- Inconel

- Hastelloy

- Monel

- High-grade stainless steels

2. Reinforced Construction Techniques

- Solid-bar machining for structural integrity.

- Consistent wall thickness achieved through deep-bore drilling.

- Reduced root diameter for minimum stress concentration.

3. High-Pressure Ratings

A thermowell shall be designed to meet excessively high pipeline pressures as found in the UAE’s oil, gas, and utilities services.

4. Thermal Resistance

Designs must have the capacity to withstand being in constant fire, heating, boilers, and high-pressure steam.

5. Dimensional Accuracy

Close tolerances are required to cope with the mechanical stress and prevent fatigue breaks, especially in high-flow formats.

Thermowells’ Design for High Pressure and High Temperature Services in the UAE

System-related designs of thermowells are required for better control of flow systems:

1. Tapered

Known for increased strength and less vibration.

2. Straight

Works under moderate pressure or flow applications.

3. Step

Have fast reaction times.

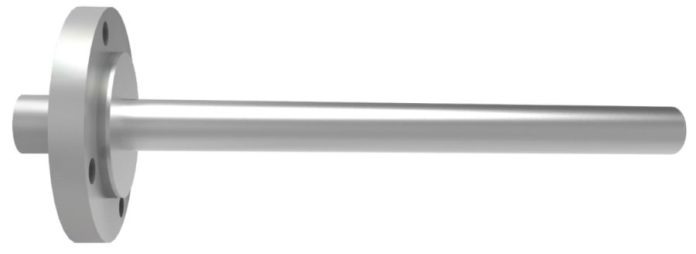

4. Flanged

Used in heavy-duty commercial and industrial applications.

5. Threaded

Best suited for small pipes.

6. Socket Weld

Perfect for high-pressure applications.

7. Van Stone and Custom Designs

For retrofits or unique settings.

Use Cases in Major UAE Industries

A stable and precise thermowell can be used in the following:

1. Oil and Gas

High-pressure transit pipelines, refineries, gas treatment, and injection plants.

2. Petrochemical and Chemical

Process loops and reactors are corrosive and operate at high temperatures.

3. Power Plants

Steamlines, turbines, boilers, and heat recovery system generators.

4. Desalination Plant

High-pressure brine and pump systems.

5. Metallurgical and Cement

Kilns, furnaces, and heat treatment zones.

6. Cooling and Utilities

Temperature sensing in pressurised networks that need protection.

Performance Benefits of Engineered Thermowells

UAE industries, in particular, benefit from well-designed thermowells that enable:

- Greater operational security at extreme conditions.

- Less risk of damaging sensors and failure in the pipeline.

- Longer thermowell and sensor lifespan.

- More accurate temperature measurement.

- Lower maintenance costs.

- More aligned with the UAE’s industrial safety standards.

Selection Guidelines for UAE Conditions

Consider the following when selecting a thermowell for systems requiring high pressures and temperatures:

- Atmospheric pressure, process flow rate, and temperature.

- Resistant to most chemicals or other harmful liquids.

- Correct length of insertion, diameter of bore, and geometry of tip.

- Requirement for vibration-control devices, including helical strakes.

- Design service of stress analysis and special design is available for product development.

- The correct choice means safety, long years of duration, and efficient operations.

Final Words

With the growth of the oil and gas, petrochemical, power generation, and desalination industries in the UAE, the need for reliable temperature measurement instruments has also been increasing. Thus, a well-engineered thermowell is pivotal to the sustainability, integrity, and efficiency in these harsh environments. They protect sensors, preserve measurement accuracy, and resist high pressure, high temperature, vibration, and corrosive media.

For industries seeking dependable, certified, and application-specific temperature measurement solutions, Tempsens stands out as a trusted expert known for engineering precision, advanced materials, and proven performance in UAE industrial applications.